Dewpoints and Indoor Humidity

With the record setting dew-points in my region, I thought this would be a great time to measure success of our hydronic radiant ceiling cooling system.

The nearby city of Vancouver set an all-time high dewpoint of 23C recently (typical of Texas or Alabama this time of year).

This would result in any object placed outside, with a surface temperature of 23C or less, accumulating condensation.

If the air volume inside of the house had these same conditions, I would be limited to only running 25C (dew-point plus 2C safety margin1) conditioned water through the ceilings, or else I would have condensation forming on my ceilings and any piping carrying that water.

I am using hydronic ceiling radiant panels to heat and cool the interior of the dwelling. This entails circulating heated or chilled water through PEX piping, installed in radiant aluminium panels. This assembly is sandwiched just below the drywall surface. (see Hydronic Circuit Complete).

Circulating water with a temperature no lower than 25C, would not provide the rate of cooling needed to maintain the dwelling at the setpoint of 23C-26C, and the cooling system would be deemed a big disappointment.

What is worse, is when you take hot muggy air and cool that air, the humidity raises even higher. This is because as you cool an air mass, the molecules in the air start to huddle closer together to stay warm, and slow down. As the water vapour molecules slow, they gradually lose their independence, and eventually buddy up and form liquid water molecules (condensation). This condensation is liquid water molecules ‘falling’ out of the cooled air volume. So as air cools, the ability to hold moisture in vapour form decreases, lowering the percentage/ratio of moisture molecules that air now contains (ratio, or relative humidity (RH), represents the maximum volume of water vapour molecules, a mass of air can contain at a specific temperature and barometric pressure).

The opposite is true when you heat an air mass. This is why you can take 90% RH 10C winter air and heat it to room temperature of 21C and the humidity level falls to 47.8%RH, a completely comfortable indoor relative humidity. In regions where the winters are cold and dry, humidification is often desirable in homes, to provide a comfortable indoor environment.

So, how did I design our space conditioning system to be a success in the record setting summer conditions?

The first, and most important, was to make the house air tight. At <0.3 air changes per hour at 50 Pa, I have very close to zero infiltration of outside air, at normal outside conditions (normal day without significant wind). This, paired with a whole dwelling mechanical ventilation system, means I am exhausting any created indoor humidity (showers and cooking are the big ones, followed by the moisture in the air that we, as mammals, breath out), while limiting any moisture being brought into the house from outside.

It means I am controlling the introduction of outdoor air into the dwelling. I have a single point of entry, via an eight-inch metal duct feeding air into my HRV (Heat Recovery Ventilator). This provides an excellent opportunity to remove moisture from that incoming air, by means of a hydronic condensing coil.

It is only by placing so much emphasis on the air barrier of the dwelling, that I can get away with using a small condensing coil in the HRV air intake. In a ‘normal’ spec house, with significantly more infiltration2 loads, a significantly larger dehumidification system would be required.

I purchased ThermAtlantic’s chilled water coil for this purpose. The water circuit feeding this coil has its own circulator, and is fed directly from the buffer tank (not through the mixing valve). This allows me to feed the coil with water temperatures well below the dew-point of the indoor and outdoor air (I just have to ensure all piping going to the coil is well insulated and vapour sealed so condensation does not form on the piping).

Here you can see condensation forming on the cold piping. If this was hidden in a wall or ceiling it would lead to decay of the structure and probably fungal growth. I will wrap this with vapour tight insulation so that the interior air is not able to make contact with the chilled copper pipes

Currently, I am maintaining the buffer tank, and therefore able to feed the condensing coil, with water temps between 8C and 19C (46.4F to 66.2F).

Seams still have to be sealed with tape and mastic.

SO, putting this altogether, what does it mean? Does the system work or not??

Well, I can say without reservation, that it has been a huge success, and for the first time in my life, I am living in a dwelling that is super comfortable in both winter and summer conditions.

Let’s look at the results. I picked a time representing the highest outdoor dewpoint I recorded on July 31, 2022 with my DAVIS Vantage PRO2 weather station. As you can see by the below graphic, the outside temperature was 27.7C/81.9F, humidity was 60%RH, and dewpoint was 19.2C/66.6F (represents 14.17 g/kg – grams of H20/kg of air)

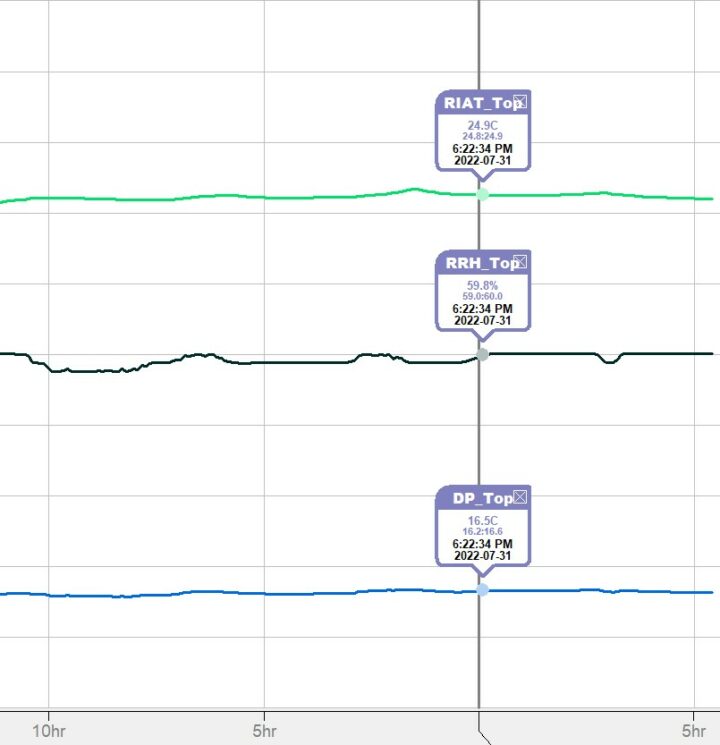

My indoor conditions at that point, shown in below graph, were 24.9C/76.8F, 59.8%RH, and a dewpoint of 16.5C/61.7F. This was the top floor conditions (the highest levels in the dwelling) (represents 11.86 g/kg – grams of H20/kg of air)

On the surface this does not look that exceptional, 60%RH outside and still 59.8%RH inside. What is all the hype about??

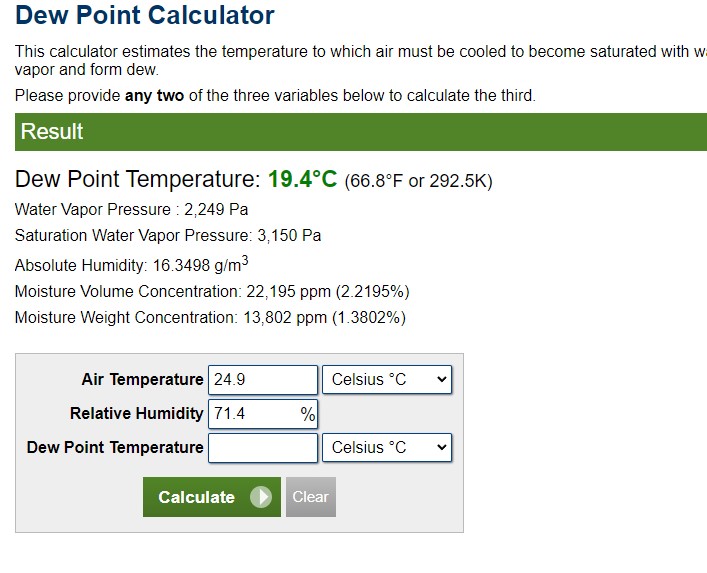

Well, when you take into account the drop in temperature from 27.7C to 24.9C, the outside air once cooled, would have had a humidity level of 71.4%RH and a dew-point of 19.4C, if it had not been dehumidified.

Figure 5 https://www.lenntech.com/calculators/humidity/relative-humidity.htm

Figure 6 https://www.calculator.net/dew-point-calculator.html?

If this air was not desaturated in some form, and with our 2C safety factor, we would only be able to run cooling water just over 21C/69.8F or hotter.

Not very cool is it!!

Now, what we actually were able to run, due to the significant desaturation that occurred in the ThermAtlantic condensing coil installed on the HRV intake duct, is shown in figure 4 above. We were able to lower the humidity from the unconditioned level of 71.4%RH to 59.8%RH, and the dew-point from 19.4C to 16.5C. 18.5C (inc. safety factor), represents a much higher cooling potential over 21.4C, does it not! For those down south of the border, that is 65.3F.

What do these results mean? How much water was removed from this air stream to achieve these results??

The calculator I used for Fig 5, also provided the grams of moisture per kg of air for both the outdoor and indoor conditions. We dropped from 14.17 grams of moisture per kilo of dry air down to 11.86 g/kg. This means, somewhere in the process, we lost an average of 2.31 grams of moisture for every kg of air we brought into the house.

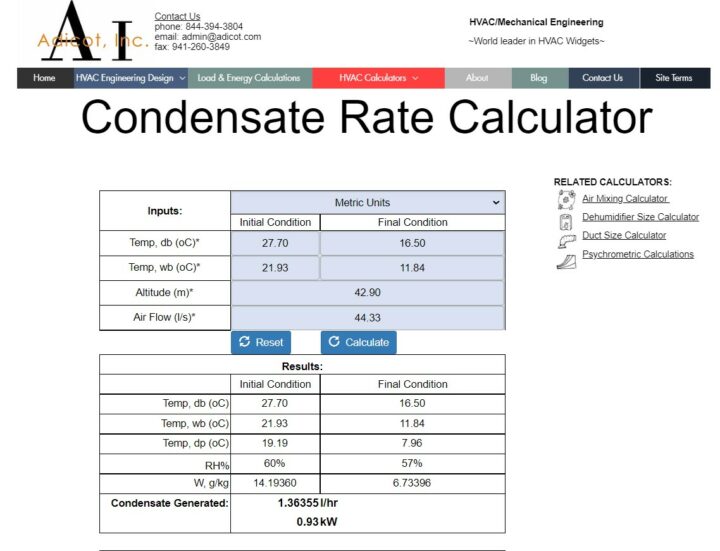

We know that air weighs 1.222 kg per cubic meter at sea level. My site is 42.9 meters above sea level, and the HRV air intake is moving a volume of 2.66 cubic meters of air per minute (93.94 cfm verified with a hot-wire anemometer).

How much moisture has been removed from this air mass??

There are lots of complicated formulas to help figure this out (to do with enthalpy and entropy – all well above my pay grade!), but I am lazy and like to find online-calculators for my needs.

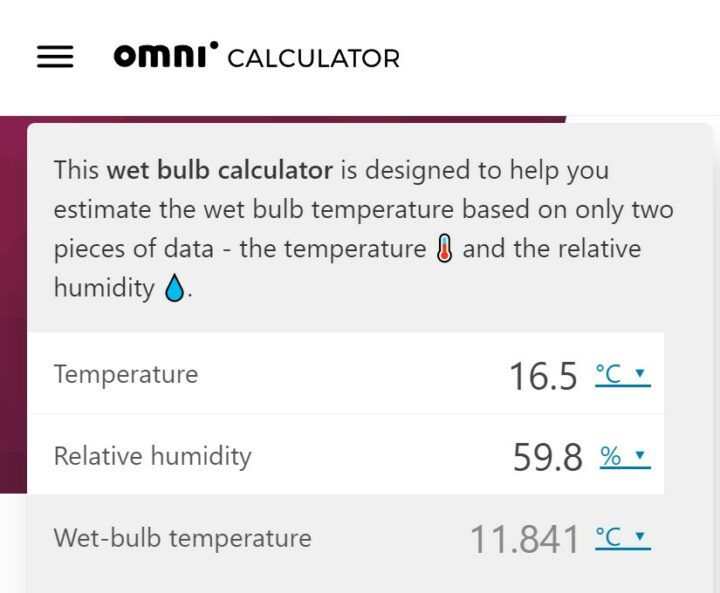

Calculate Wet bulb temperature using temp and humidity

Plug in all of our data, including the wet-bulb temp above, to find total condensate removed.

Using these two calculators, we can see that on average, I am removing 1.364 litres (.36 USG) of condensed liquid (condensate), and .93 kW (3,412 Btu) of energy from that air stream every hour.

Not too shabby for a small coil with only 94 cubic feet per minute of air flow through it.

End result – A very comfortable home! 🙂

In future updates I will document the energy being consumed to create this conditioned water and the efficiencies a heat pump affords. I will also discuss how comfort at higher AIR temperatures in summer and lower temperatures in winter, can be maintained due to the fact that the average surface temperature of the objects around you is lower/higher with a radiant system.

As always, I appreciate you visiting my website. If you like this content, please subscribe to our journal (bottom of our home page), to ensure you are notified when we add new posts.

1 When cooling a dwelling with a radiant system (objects are cooled, not the air), it is important to keep surfaces above the dewpoint of the interior air. If a surface reaches the dewpoint, condensation will form on this surface. In the case of a drywall ceiling or wall, this would lead to degradation of the drywall and possible fungal growth. By maintaining the chilled water above the dewpoint, you don’t need to worry about moisture formation on the visible surfaces or the piping hidden in the wall and ceiling assemblies.

2 Infiltration represents air that enters your home at uncontrolled entry points. These would include leaks in and around doors and windows, leaks between vented crawlspace and main dwelling, leaks in exterior walls around electrical, low voltage, and plumbing penetrations, and finally leaks between all walls/ceilings and vented attic assemblies. This infiltration air is unconditioned, so will be at or near outside temperatures, and bring with it all the moisture (and contaminates) that it contains.

“Correction does much, but encouragement does more.” —Johann Wolfgang von Goethe (1749-1832) Philosopher, Scientist, Author

“We do not inherit the land from our ancestors, we borrow it from our children.” —Native American Proverb

“A dream doesn’t become reality through magic; it takes sweat, determination, and hard work.” —Colin Powell (born 1937) 65th U.S. Secretary Of State

Sean, you should calculate how much sensible cooling is also provided through your chilled HRV ductwork and comment on whether it is a significant factor or not in helping achieve your indoor comfort.

Great idea, I calculated latent, but not sensible cooling. Will try to get to this soon.