Out for the count

The last week has seen reasonable progress in the ‘hole’.

I finished cleaning out and re-attaching the bag footings on the inboard side of the foundation and then worked with Pat from embers to level the gravel for the first 48″ around the inboard side of the foundation to allow for the double thickness of sub-slab rigid foam.

I then prepped the interior footings (I again had to clean out the debris between the poured concrete and poly to prevent the poly from being torn, as this acts as both the water and air barrier), before back-filling the gravel around the footings to the finished height needed for 1 layer of sub-slab foam.

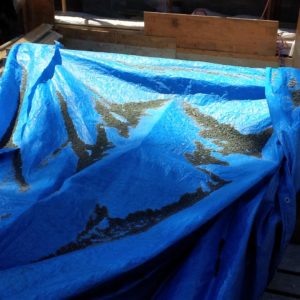

With all of the prep complete, I called in RRR Slinger Services for two loads of 3/4 crush ($930 + tax for both loads). Boy what a difference between RRR and the previous slinger I hired a couple of weeks ago! The RRR operator’s fingers were constantly moving, adjusting the conveyor speed, and exit angle in both the vertical and horizontal plane. The result was a nice smooth, evenly distributed layer of gravel across the pit floor. The only issue was how high to tell them I wanted the gravel, the slinger was too loud to hear the beeper on the laser level, so I went by eye and ended up a couple of inches too high in spots.

With all the stone delivered, I started systematically setting the finished gravel heights throughout the pit using the laser. I hired Calvin from Embers yesterday to move the bulk of the gravel while I did the final adjustments with the rake.

Fortunately most of this was completed by noon, because at about 12:10 PM, my life went sideways fast. Another task that Calvin and I were to complete Thursday was to unload 102 bundles of ROCKWOOL Comfortboard IS – Semi Rigid Mineral Wool – that will be applied to the exterior side of the foundation after waterproofing. The 52′ Semi had arrived and I was just opening up the gate when I tripped backwards on a piece of broken concrete curb at the side of the road. I reached for the construction fence behind me to stabilize myself, but because the panel was now unlocked, it just pushed further away from me and in the process I dislocated my left shoulder. I then completely lost my footing and rotated towards the ground where I fell on the same shoulder popping it back into place but in the process I fractured the head of my humeral arm bone.

I was done and the pain was unbearable. My neighbour Gail took me to the hospital where I spent the rest of the afternoon with X-Rays and getting the pain under control. Calvin and the truck driver spent the next 2 hours unloading the insulation by themselves. I was so lucky that Calvin was there that day and am extremely appreciative of the truck driver for his herculean effort in unloading all of those bundles.

I see the specialist on Monday but suspect I will be off at least 6-8 weeks. At least it was not more serious, we have received the first draw, and I am at the end of a stage where stuff can just sit for a bit. But boy does this suck (and hurt). I am thankful for modern pain killers!

Thanks for visiting.