ICF Rising

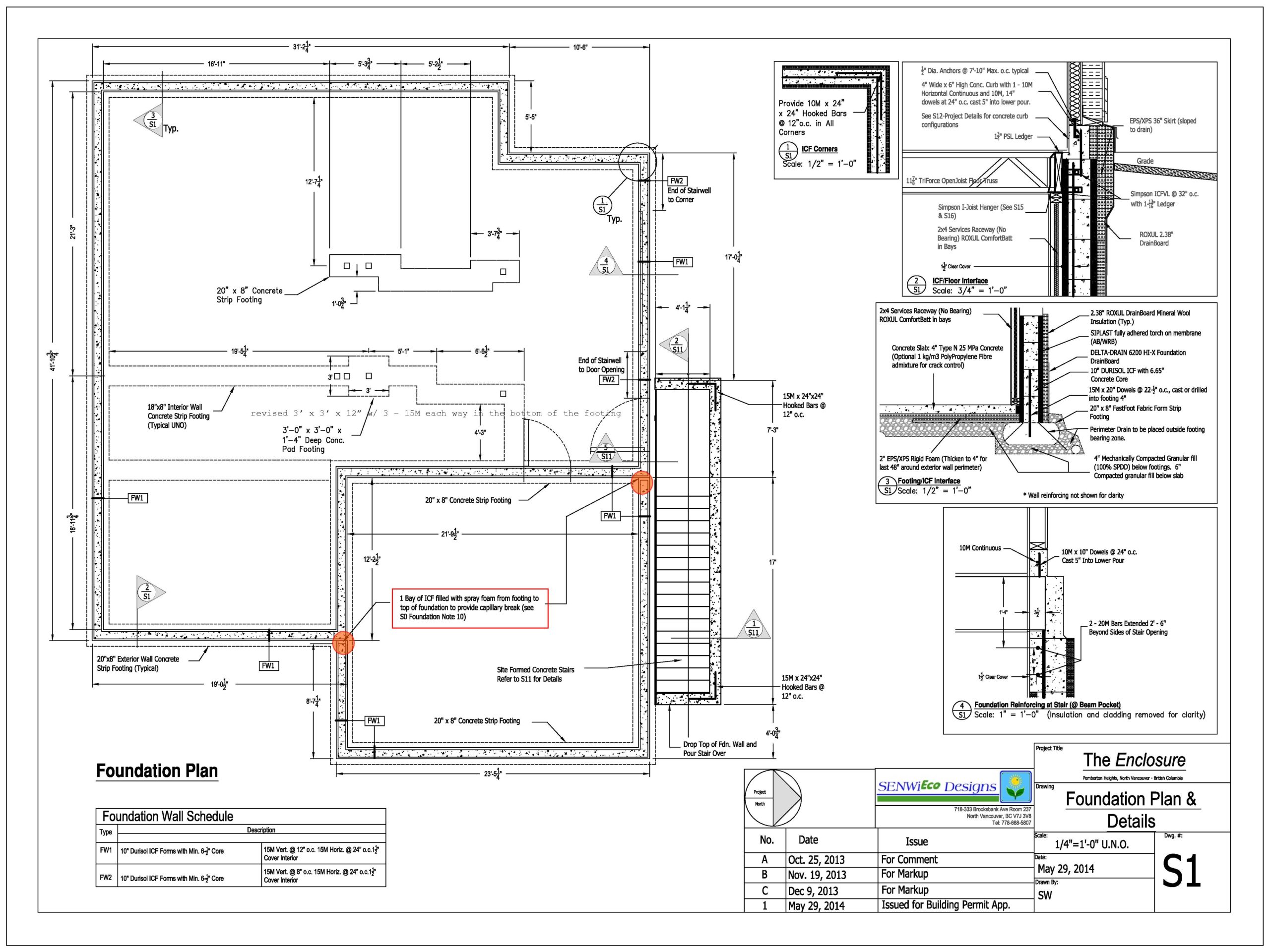

The last week has seen some great progress at the site. By last weekend, I had all the forms stripped, all the form wood sorted and stacked, and had started the second row of ICF.

Monday was a light day on site as I assisted Anna and also grieved for the loss of her mother. It was quite a shock and very sad. It will take some time to get used to the fact she is gone.

In the afternoon I resumed my plans to pick up some new scaffold up at Scaffold Depot as I really needed some time alone anyway to process the mornings events. Scaffold Depot was selling off 78″ x 60″ Arch Frames for $25 ea. This is a fraction of the reg cost. These were new frames that had been sitting in the yard for some time. They are a bit taller than normal which will both help and be a problem depending on what task I am using them for. I bought enough to do a double layer along any of the four elevations of the house. Once the house is complete, I should be able to sell for the same or even more than I paid (used frames were more expensive on Craigslist). I needed a two frame tall tower in order to create a way to get out of the pit once the ICF wall is too high to access the existing ladder. I will need to build a sky bridge from the top of the pit wall over to the tower. I may also use the scaffolding to provide part of the walk surface that will be needed for pouring.

Tuesday, I had a cornucopia of help. My Father-In-Law came by and brought a friend – Bert, who was also the fellow who donated all of the longer lumber I brought home a few weeks back. Ted also came by and in 3.5 hours, the three of them and moved about 100 of the ICF blocks from the stockpile at the north end of the site, so that they were all stacked around the perimeter of the foundation. This made progressing on the next few rows of ICF easy and also reduced the strain on my back. As I had only had about 4 hours of sleep (got up at 5 AM to take my wife to air port) and had a back appointment in a few hours anyway, I took them all to lunch and called it quits, but not before finishing the second row of ICF and erecting the scaffold tower.

Wed & Thursday saw the third course of ICF installed, and Friday saw the 4th course in place. I also picked up a Colphene 3000 sample from James Kelly at Soprema, that I am testing for adhesion to the ICF and bag footing, as this is planned as the primary waterproofing barrier on the foundation.

This is a good segue to discuss the latest roadblock from the District. A full 9 months after approving my drawing package that made it clear what I was using for a foundation wall (Durisol ICF), and the fact that I was using a self adhered membrane as my primary waterproofing solution, they in their infinite wisdom have changed their mind and are now forcing me to have the waterproofing plan approved by a building envelope engineer. The logic used was because Durisol is not made from foam (the only ICF specifically approved in the building code), then not only do I need to have the structure of the foundation wall professionally design (I had already done this), but I now also could not use a Part 9 waterproofing approach and would need to have the system designed under Part 5 and signed off by an engineer. Is there one iota of the code language that supports this jump in logic? No! There is nothing that links the structural design of a foundation to the waterproofing of the foundation. They are two different tasks not mutually dependent.

And in fact the Durisol ICF block does have Part 9 approval by means this letter of approval issued by the Ontario Building Materials Evaluation Commission. The only reason I had my wall engineered, was that I had a higher unsupported wall than was approved by Part 9. But facts do not seem to matter in this District, and I suspect the manager did not even review the literature I provided them when the concern was first raised. SO now I am wasting more money and time to jump through their bureaucratic hoops. I cannot say enough positive about the inspectors and staff. They have been great and very supportive. It is the Manager that I have a beef with as it is always his way or the highway, and his way at least appears to be whatever leads to the lowest level of liability or effort by the District. Revisions to the Municipal Over-site of the code cannot come soon enough!

Fortunately, I know the system works as it already has been reviewed by my mentors in the building science field, and I have a large number of building envelope specialists I can draw from and have passed the request onto a engineer I know from the BC Building Envelope council. He has been too busy to get to it this week, but I hope we can wrap this up by next week.

Today I gave my back a bit of a break (it has been doing remarkably well thanks to the Vancouver Spinal Decompression Centre) and only spent a few hours on site cleaning up some of my outstanding tasks. I also picked up some plywood that will be used for the sky bridge and bought some ROCKWOOL Comfortbatt that I used to fill two of the ICF bays in each course to create a thermal break between the main dwelling and the room under the garage. With the structural engineer’s blessing, these bays will have no concrete or rebar penetrating them. This will allow the thermal barrier to be continuous around the entire outboard perimeter of the main dwelling. I started out with spray foam, but it was expensive and even the contractors sized can (that needs the applicator gun) did not do more than about half a block high. These thermal breaks will require extra vertical reinforcement at the bay on the garage side of the column, but this is worth the extra $10 or so.

I also re-positioned the roving cam to the top of the pit wall as a few of you had advised that the view from it was very restricted. The new vantage point allows you to see most of the pit and will not be blocked out as the wall rises.

Next week will slow down a bit as once I finish the 5th row, I will need to build scaffold around the site to complete rows 6 through 9 and form up the top curb. I am aiming for the foundation ICF and form-work to be complete by second week of March. I will then need a structural inspection and a District inspection (but not before I have letters of authorization and assurance from the Building Envelope engineer).

Thanks for visiting!