Final Foundation Push

Sorry for the silence folks, I have been on the final push to finish off the foundation forming. I have my structural inspection, and also my survey, scheduled for Tuesday the 7th, and will try to schedule the District’s inspection for the 9th or 10th latest. If all goes per plan, we will pour the foundations on Monday April 13th!

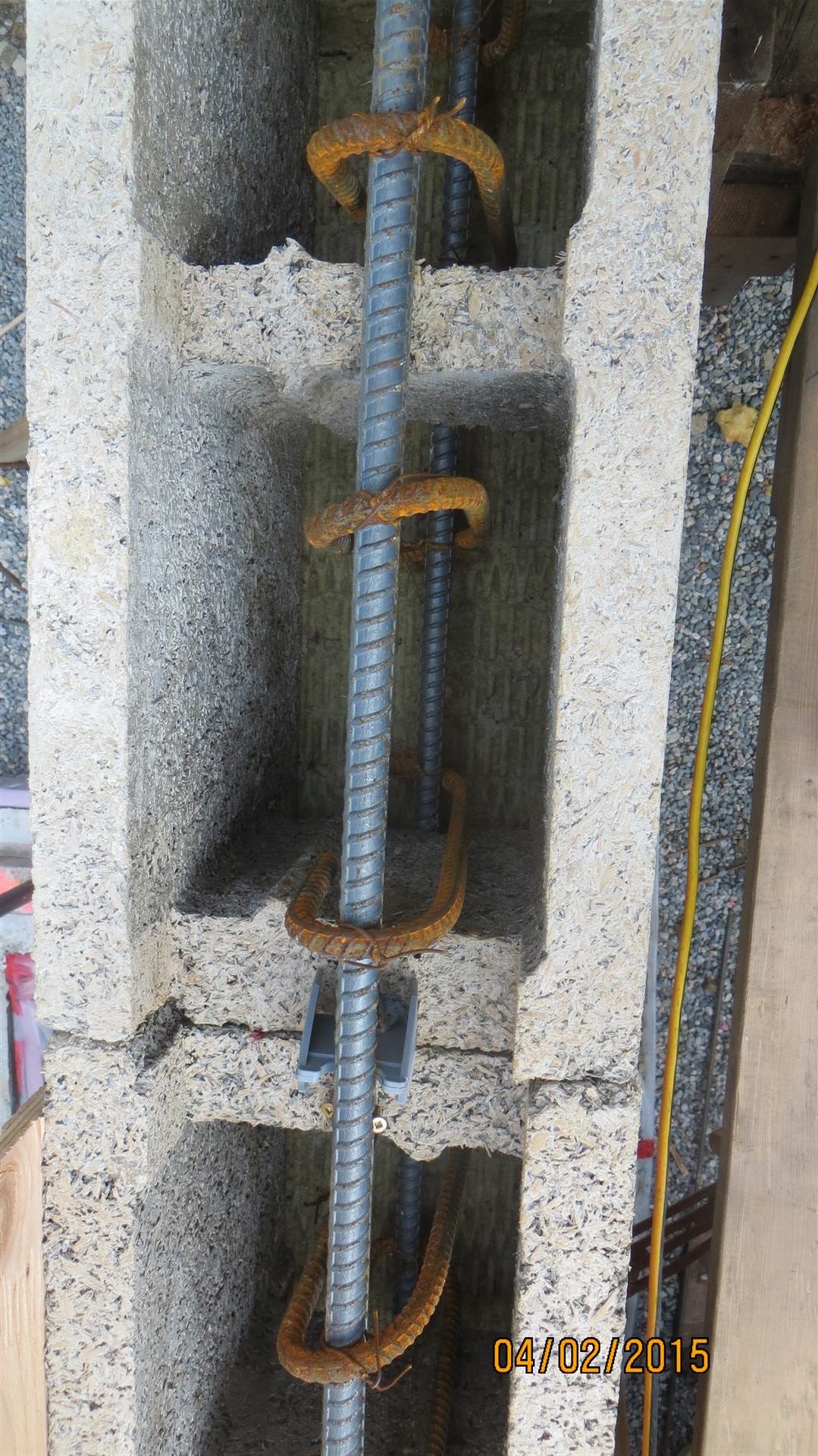

Over the last 10 days I have finished placing all of the rebar (vertical rebar secured to top row of horizontal rebar, rebar for the lintel over the basement walkout door, 2x 20M bars that will strengthen the foundation beside the basement stairs up to the first floor) and also started forming the top curb that sits around the perimeter on top of the ICF.

I had a setback on the rebar, made a mistake on a dimension and ordered about 100 bars a foot too short, but worked through it (reordered) and will be able to use the shorter bars for much of the basement walkout stairs and retaining wall.

Placing the vertical rebar is a real challenge in ALL ICF construction (regardless of manufacture). There is no way to ensure the bottom end has the proper concrete cover and will stay in place during the pour. I was more fortunate than most because I poured my first row of ICF with the footings, did not fill that row to the top, and did not smooth out the concrete inside the bays of that first row. This generally allowed me to find an appropriate divot in the first pour to ‘anchor’ the end of the vertical bar into. I would then give a good smack with the hand sledge to seat the bar in the divot and then tie off the top of the vert bar to the horizontal. If I did not find a suitable crevasse to anchor the bar into, I sharpened one end of the bar with a grinder and then pounded that end into the concrete to secure. I cannot guarantee it will work, but it will be better than most other ICF jobs I am sure. If I was to do this again I would look at placing an extra 10M horizontal rod at the first row, just off the inside face of the ICF, to sandwich the vertical between the 10M and the regular 15M horizontal bars (placing the horizontal bars to ensure the vert had 1.5″ cover). Or I would look at putting in rebar caps upside down into the wet footing concrete to capture the vert bar when lowered later from the top. The vert bar is a problem with ICF installations (below grade), and I am aware of a recent $1M lawsuit in West Vancouver against the ICF manufacturer and engineer of an ICF foundation where the bar was not properly captured by the forming process and on investigation some of the bar was even able to be pulled right out of the foundation without the use of tools.

Over the next couple of days I hope to finish the form work and hang the final 10M bar that is to run continuous in the top formed curb. Next week I will have to install the block outs for the first floor doors and the basement beams, and also install the various electrical, plumbing, and vent pipes that will be penetrating the foundation. I will also need to brace all of the cut joints in the ICF, install the remaining uprights to secure the wall, and finally install all of the diagonal bracing to secure and plumb the wall prior to pour. It will be a very busy week!

One of my favourite quotes of late (and most relevant):

“I am only one, but I am one. I cannot do everything, but I can do something. And I will not let what I cannot do interfere with what I can do.” —Edward Everett Hale (1822-1909) American Author

Thanks For Visiting.