Fleece Lining

Hi Folks,

Sorry again for the long absence, it has been a crazy time, with 60-70 hour work weeks!

I have a lot of updates to share, and some will be out of order, and provided later, as I try to cover the big updates first.

When I last updated you, I was preparing for the insulation crew, scheduled for Jan 4. In the end I pushed them back till Jan 11, and over the next three days they completed the exterior stud bays on the main and upper floor, the 1st floor ceiling (for sound proofing and also required by the hydronic ceiling radiant panels to ensure the heat is pushed down and not escaping into the ceiling cavity above). I also had them insulate the interior walls on the top floor between all 4 bedrooms for sound proofing.

Lets start with a short pre-insulation site visit.

Quick Review after first night, followed by a general review at the completion of the task.

In the above video, I kept remarking on the sound deadening capabilities of the ROCKWOOL COMFORTBATT.

They truly were remarkable, so I thought a quick demonstration was in order.

You can see for yourself, the phenomenal performance of this product. Right at the very end of teh video, where I am away from the missing insulation in the ceiling, you can barely hear the music in the background, even though I am only 40ft away from where it is blaring.

I mentioned I chose to use the COMFORTBATT vrs. the Safe’n’Sound for the interior assemblies I needed both thermal and sound deadening for these assemblies. When I was analyzing what was suitable for my project, I reached out to the local rep and was provided a couple of documents.

SO, because COMFORTBATT is thicker than Safe’n’Sound (provides better thermal performance), and carries a smaller price tag, I decided on COMFORTBATT for all my internal assemblies (even those that did not have a thermal barrier need, to ease the procurement process). I used 5.5″ for the 2nd storey floor assembly (1st storey ceiling) as I wanted to maximize the sound deadening in this assembly. I used only 3.5″ for the 2nd floor dropped ceilings (those that were not vaulted), as this was all the thermal resistance I needed above my ceiling hydronic heating system (more on this soon), and I did not need the sound deadening in this assembly.

Now some general notes on the completed insulation task.

Rockwool insulation is my preferred insulation material for most applications. It performs very well, is quite easy to install tightly do to its ‘stiffness’. It also does not burn (so provides a much longer opportunity to escape, for occupants, during a house fire AND does not produce noxious smoke like ANY foam based insulation). It’s also avoided by rodents and most insects, in fact the only forms of life I found that seemed to be attracted to it, were bumblebees and the Northern Flicker wood pecker, who both seemed to be very pleased with its presence.

It also is less itchy than fibreglass, but not enough to consider it not an itchy product to use. I also find it quite dirty, or more technically correct – rocky. There is a lot of broken down rock particles that fall out of the product (roughly size of sand or smaller), so you are left with more debris than some other forms of insulation. This was only a problem for me, because with my asthma, I am susceptible to dusty areas. SO I generally need to wear a good respirator when installing the product (especially overhead) and vacuum up regularly.

Some who watch the videos carefully, will notice a lot of smaller pieces used, especially on the ceiling bays. I purchased 16″ On Centre material for the ceiling/floor assembly. But I had varied floor truss spacing. SO I instructed the crew to significantly cut down their waste, and cross cut the batts when I was above or below the 16″ spacing. You take a little longer, BUT save a LOT of material. Otherwise, the standard practice for instance, on a say 12″ bay, would be to cut 4″ off of a 16″ batt, throwing the 4″ in the trash heap. All of the insulation that, in the end, will be designated as ‘trash’, will be donated on Craigslist, where it is usually snapped up by people building small sheds, or just wanting to fill gaps in the attic or crawlspace. To date, I have not thrown out ANY ROCKWOOL on this project to date. Some of the more unique projects people have accomplished with my discards was to insulate a new still at a micro-distiller, and to build a metal heating forge as a school project.

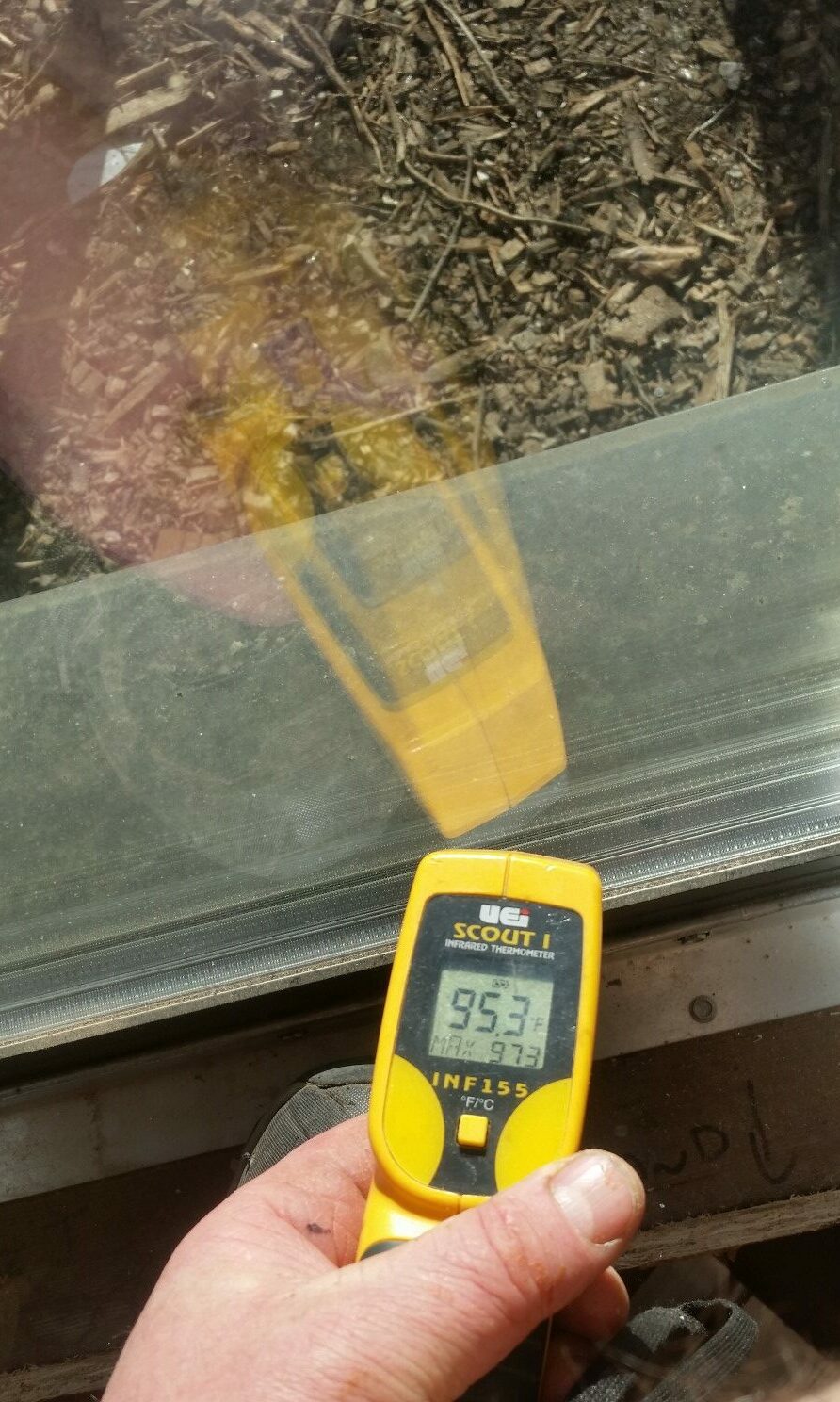

The completion of the exterior stud bays now completes the building enclosure’s thermal barrier and provides an effective R38 wall assembly! This, with our effective R66 roof assembly, has created a home with an extremely small heating footprint. On a recent cold day, I had a 16º C temperature difference between outside and inside on the main floor, with only a 1500W electric oil filled heater as my heat source on that floor, and some phenomenal thermal gain from my Cascadia Window and Door windows. I recorded the temp of the stainless spacer between the window panes at 95.3ºF (35ºC) even though it was only 2ºC outside (you measure the spacer because it is almost impossible to use an infrared thermometer on the reflective glass).

This has been the first, and only winter, of this build, where I have not cursed the cold weather. I have been comfortable in shorts and T-Shirt all winter long, protected by my lovely ROCKWOOL fleece lining!

Thanks for visiting. Please stay safe out there!

“Don’t ever forget that you’re a citizen of this world, and there are things you can do to lift the human spirit, things that are easy, things that are free, things that you can do every day: civility, respect, kindness, character.” —Aaron Sorkin (born 1961) Academy Award Winning Screenwriter, Producer, And Playwright

“Gratitude unlocks the fullness of life. It turns what we have into enough, and more.” —Melodie Beattie Motivational Author